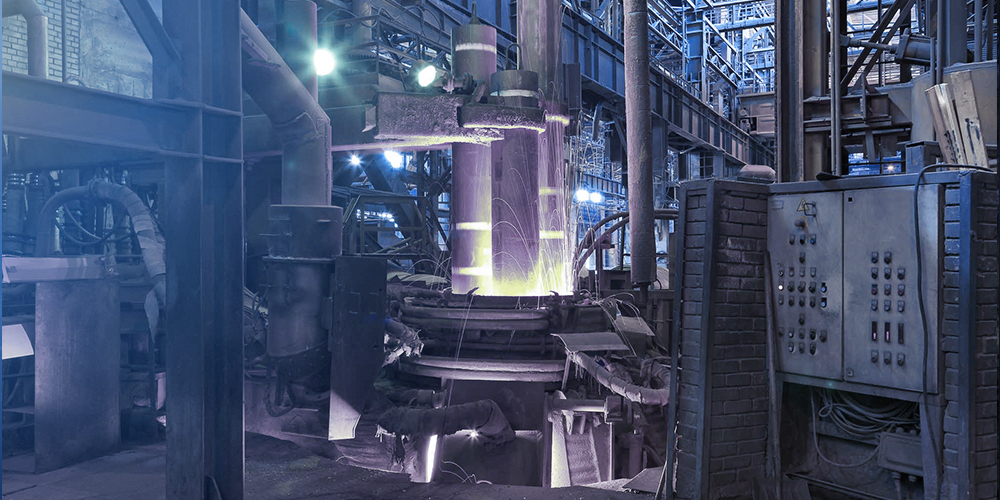

Why automation is indispensable for modern industrial companies

The demands placed on modern production facilities are constantly increasing. The aim is not only to maximize

productivity, but also to minimize energy consumption and environmental impact. Companies that optimize and automate their production processes achieve greater efficiency, increase production speed and reduce operating costs in the long term. Process automation also makes it possible to minimize human error and ensure consistently high quality standards.